Completed projects A5 SFB TR 87

High Power Impulse Magnetron Sputtering (HIPIMS)

Magnetron sputtering is a widely used physical vapor deposition (PVD) technique. In magnetron sputtering, permanent magnets are placed behind a piece of metal, a so-called target. The magnetic field confines electrons to the region close to the target, where they can efficiently ionize the working gas (usually argon). A negative voltage is applied to the target, which will attract working gas ions towards the target. These ions hit the target with such high kinetic energy that they remove atoms from the target surface on impact. This process is called sputtering. Sputtered target atoms move through the discharge towards a workpiece, where they form a coating.

High power impulse magnetron sputtering (HiPIMS) is a relatively recent variation where short high voltage pulses are applied to the target instead of a continuous voltage. The result is the formation of very dense transient plasmas with a high fraction of ionized species, improving the quality of the deposited coatings in terms of density, adhesion, and hardness. However, depositing a coating of comparable thickness takes longer with HiPIMS than with traditional magnetron sputtering.

Within the frame of the project DFG TR87, our goal is to understand the physical process inside these HiPIMS plasmas with a particular focus on finding pathways to improve the deposition rate. We employ a wide variety of diagnostic methods, such as time and spatially resolved optical emission spectroscopy, a collection of different electric and magnetic probes, and energy-resolved mass spectrometry. These plasma diagnostics are combined with surface characterization methods such as x-ray photoelectron spectroscopy, which we use to characterize the surface chemistry of the deposited films or the target.

Spokes

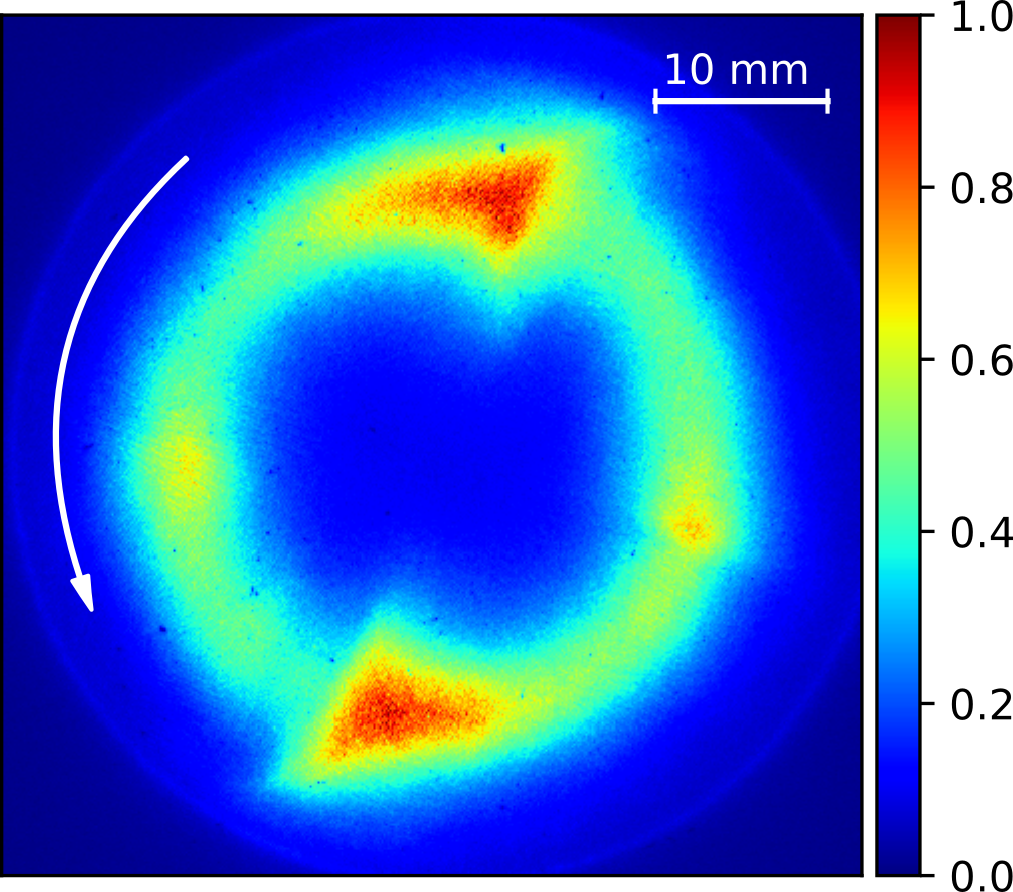

While the plasma torus formed by the magnetic field configuration (see figure 1) seems homogeneous to the naked eye, distinct structures can be observed with a fast camera (figure 2). These structures, so-called spokes, rotate along the plasma torus with velocities in the order of 10 km/s. Their increased brightness indicates a region of elevated electron density or temperature, which has profound consequences for the confinement of electrons in the magnetic trap and possibly the ion transport towards the workpiece. As such, these spokes might offer a pathway for optimizing the deposition rate of HiPIMS discharges. However, understanding these structures has proven very difficult, which is mostly due to the lack of quantitative measurements. Such measurements are very challenging since spokes emerge stochastically at random positions and times during each discharge pulse. This means that synchronization between the diagnostic tool and the spoke movement is required. Additionally, the diagnostic tool has to be very quick to reliably capture the fast spoke structure. Our goal is to perform quantitative measurements of spokes to create a solid understanding of the physical processes that create and maintain these structures. Based on this knowledge, we aim to manipulate these structures to optimize the deposition rate of HiPIMS discharges.

Videos

Here is a spoke video:

A video in German presenting HiPIMS plasmas can be found here:

Funding

The work is funded by the German Science Foundation (DFG), SFB-TR 87, project A5